Protected Flow Manufacturing for Acumatica

Protected Flow Manufacturing (PFM) is an approach to Production execution, planning and materials that is simpler and easier to understand than MRP and finite schedulers.

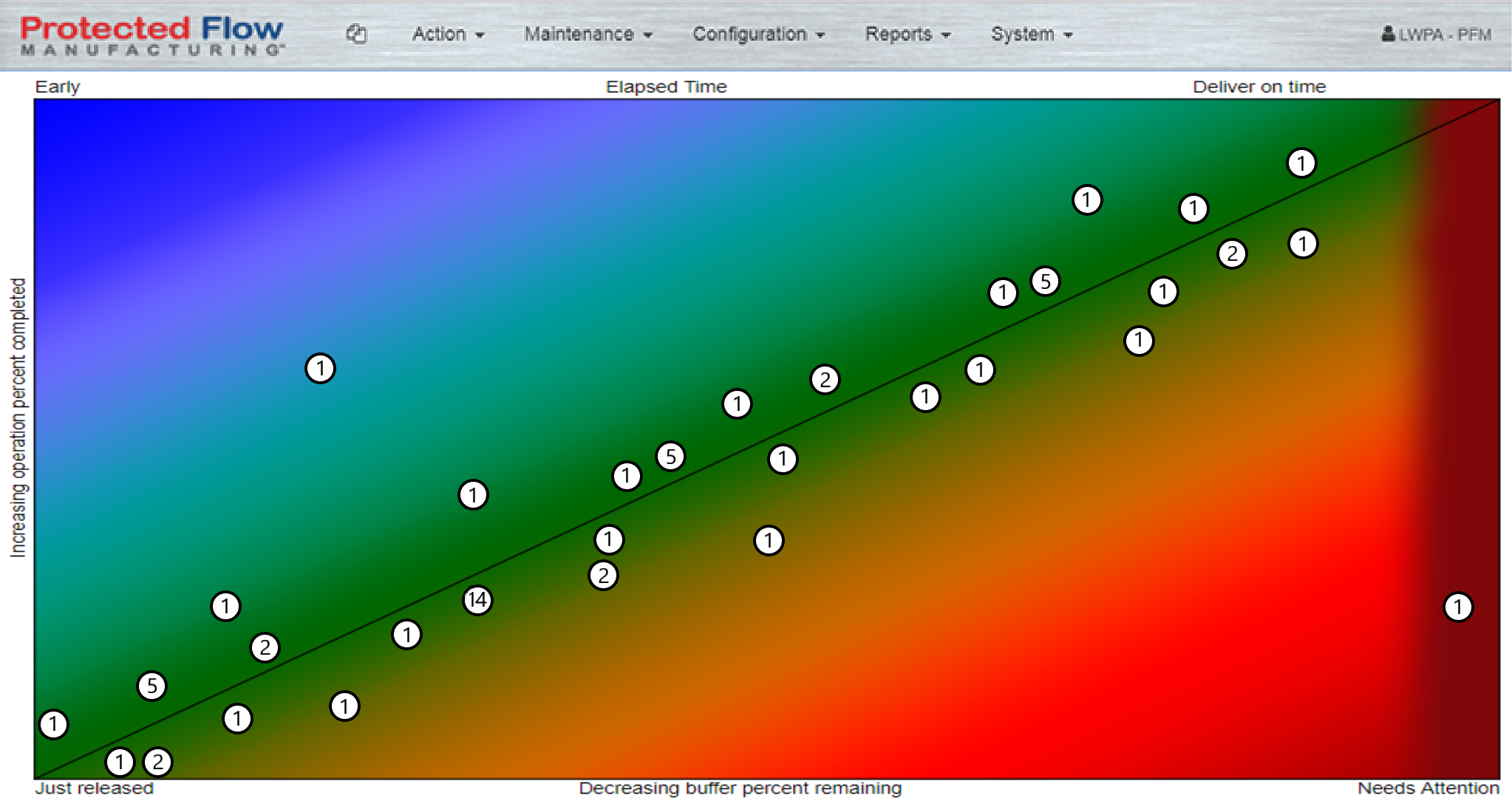

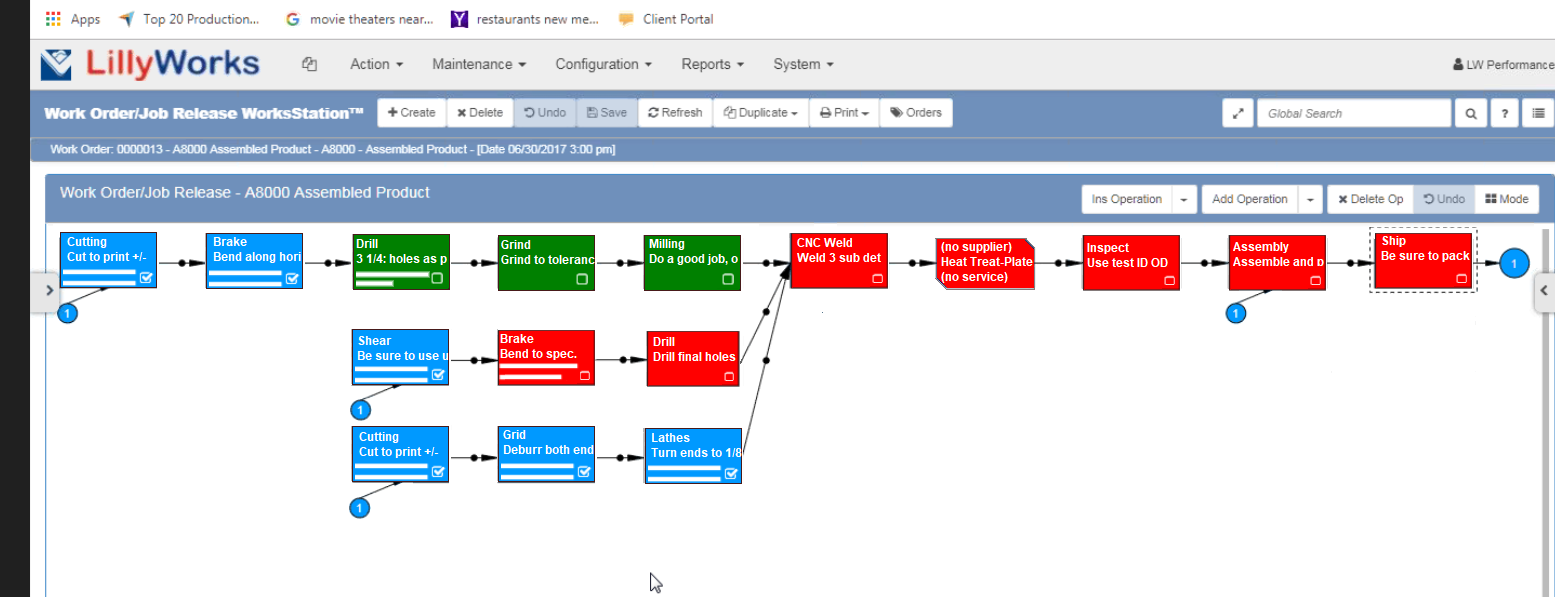

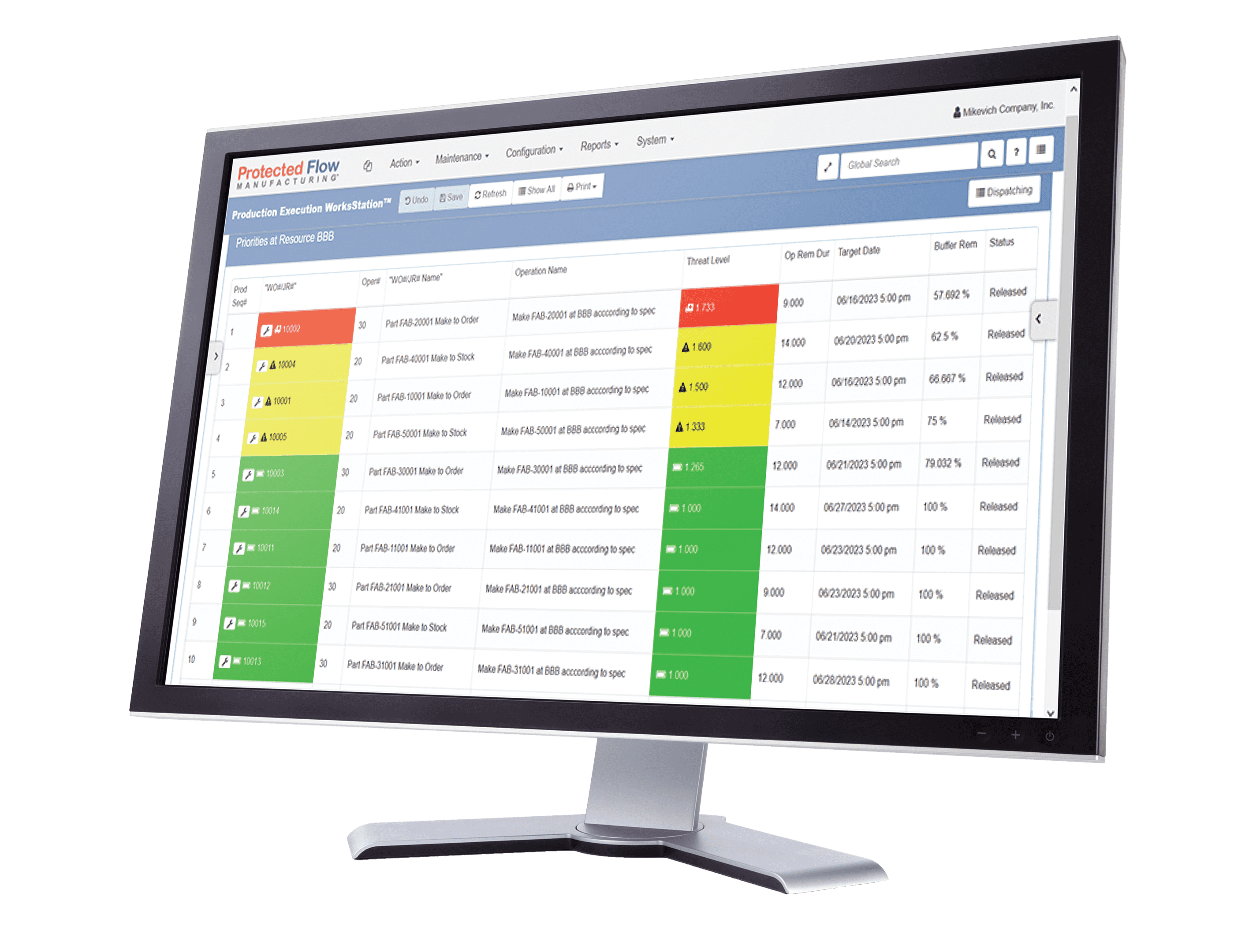

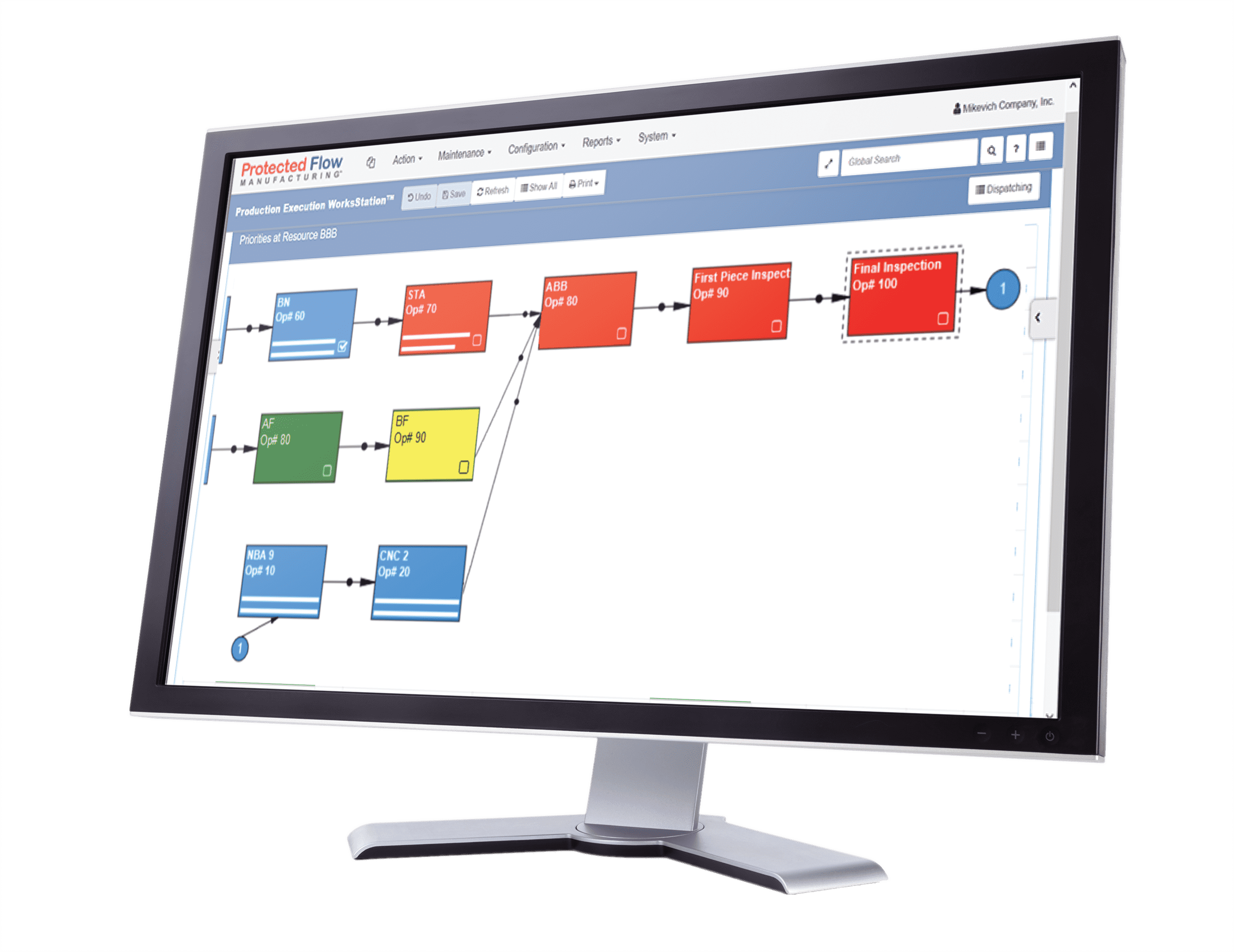

PFM's Execution toolset addresses the real-life challenges manufacturers face and reflects the realities of actual operations, whether you are operating in the mode of make-to-stock, make-to-order or somewhere in between. PFM is “better” because it respects the reality that job priorities change over time, including the ripple effect to upstream and downstream operations.

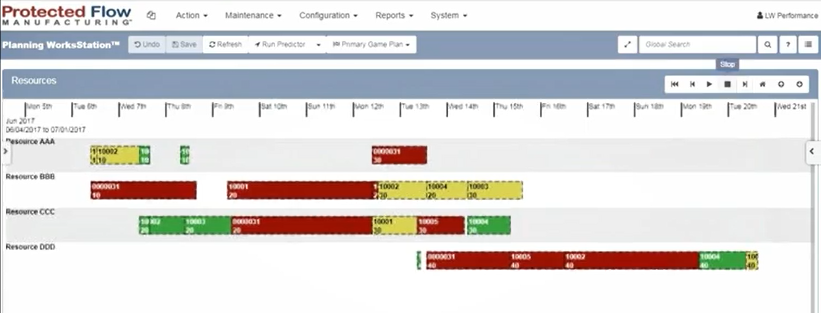

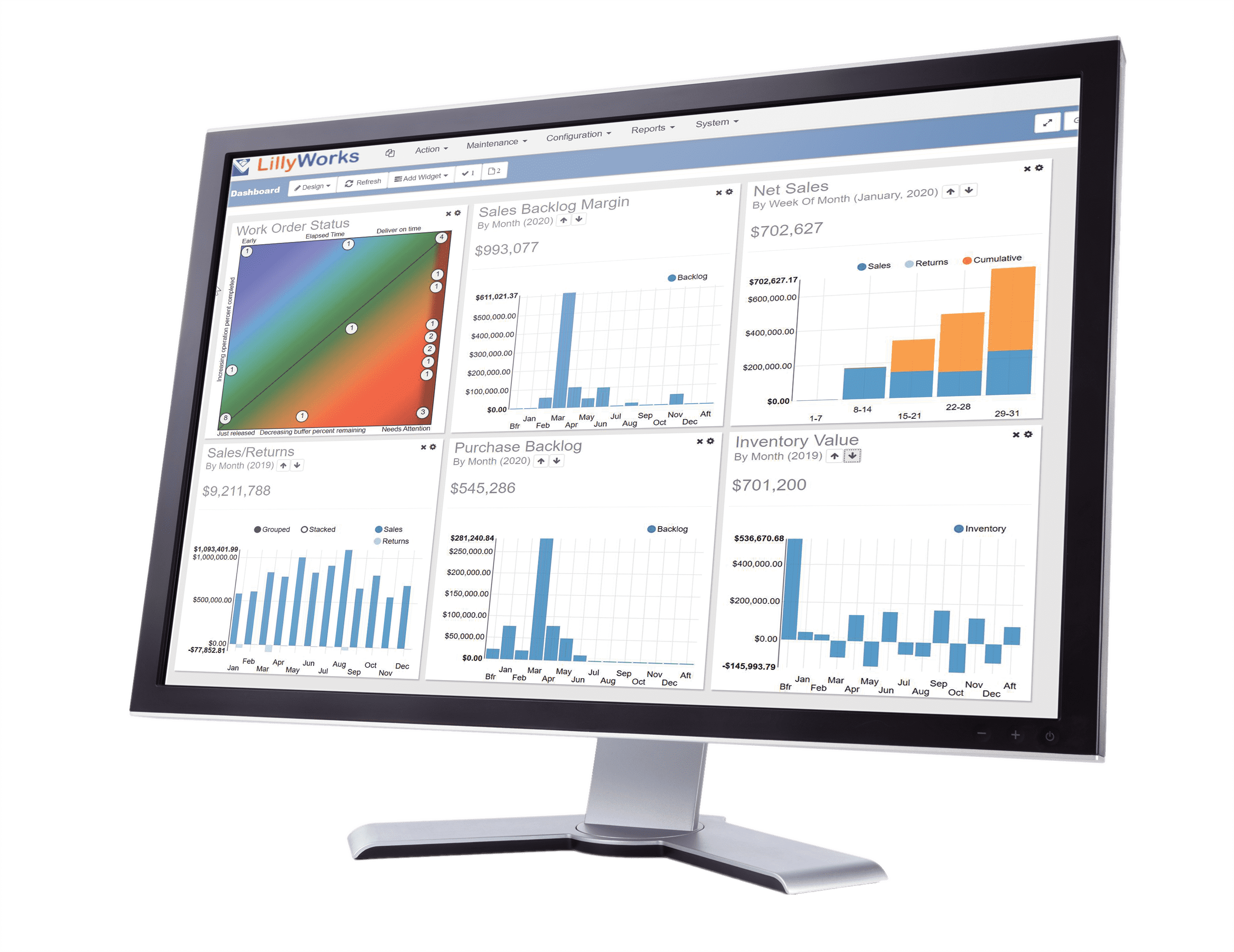

PFM's Planning toolset reflects what is likely to occur in the future when workers perform according to the priorities that it calculates for them, while also acknowledging limited capacity resources.

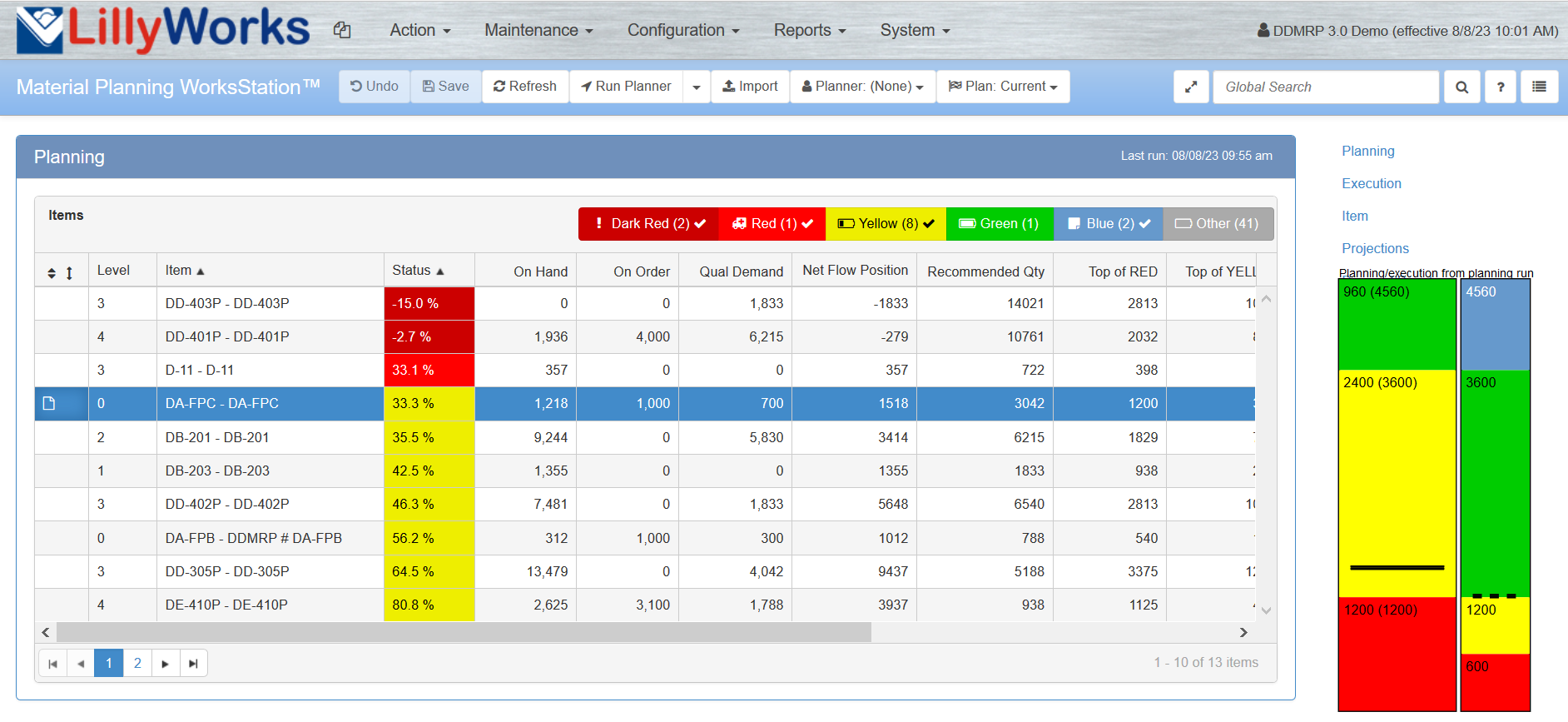

And PFM enhances the material plan with a production schedule that can be trusted and executed simply by following the rules.

If you are a discrete manufacturer struggling with gaining agreement shop-wide on what to work on next and you are interested in improving your company's delivery performance, let us show you why Protected Flow Manufacturing is the right choice to start getting real results, fast.

Key features

- Perfect for high-mix/low-volume manufacturers who need the ultimate in Shop Floor Scheduling, Planning and Material Availability.

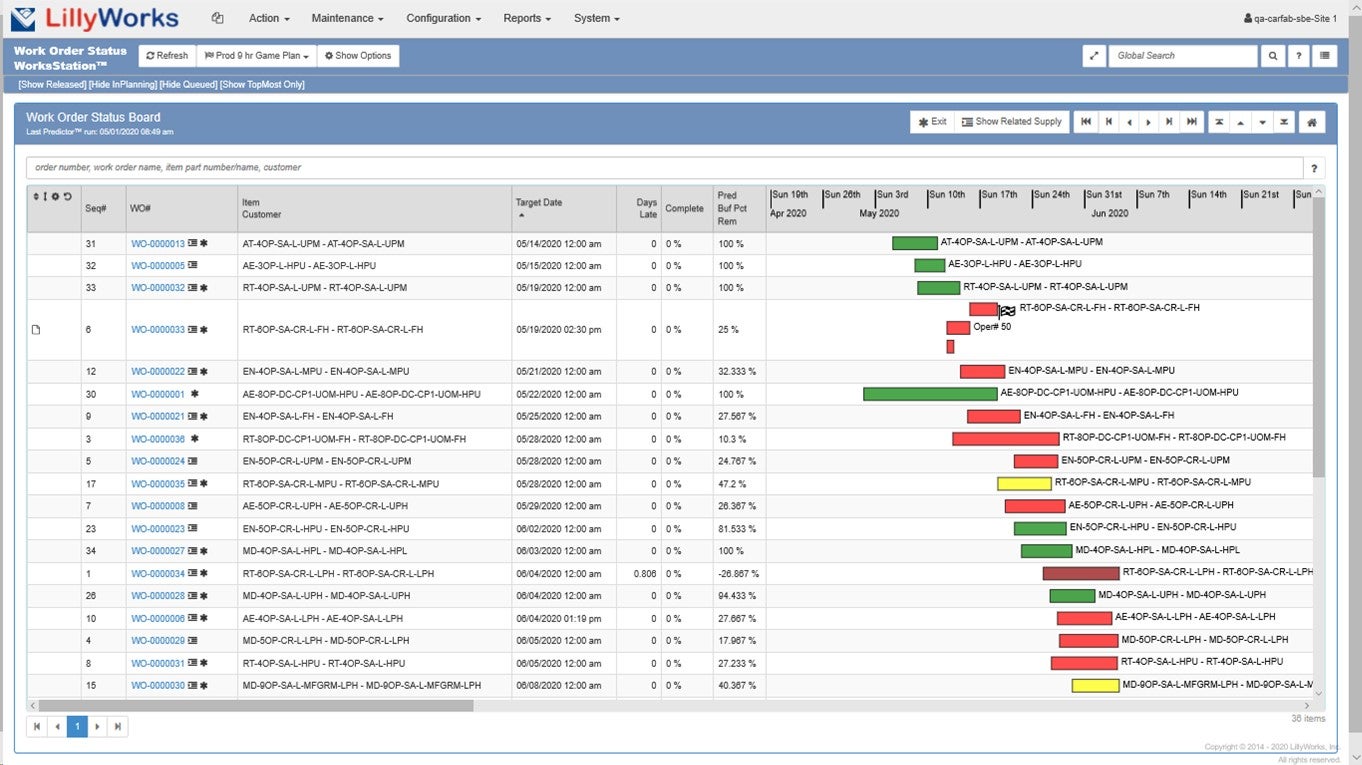

- Know exactly where all your work orders are and how they’re progressing.

- Shop-wide agreement on priorities, everyone knows what to work on next.

- Confidence in knowing when customers will receive their order.

- Predict your future by the week, day, hour, or even minute-by-minute to show issues as they're predicted to occur.

- Easily manage the due dates and dependencies for workorders with sub-assemblies.

- Prevent resource bottlenecks, increased wait times, and confusion over priorities.

- Start seeing results in 4-6 weeks!

About LillyWorks, Inc.

In 2016 the team at LillyWorks had a stark realization: The traditional model of Finite Capacity Scheduling and MRP is not working for today’s Hi-Mix/Lo-Volume manufacturers. In response LillyWorks created Protected Flow Manufacturing (PFM) as a simple, powerful approach to quickly deliver the answers manufacturers have been looking for in Production Scheduling and Material Planning software.

If you’re like most manufacturers, you need software that actually aligns with how you do business. Since 1960, our mission has been to "Create Technology That Works for Manufacturing" and along the way we have been developing solutions to help our customers meet the unique manufacturing challenges of today and tomorrow. We have a deep and successful background in manufacturing software having also created the popular ERP systems known as ProfitKey and VISUAL Manufacturing.

Now, PFM is seamlessly connected with Acumatica, so you don’t have to wait to start getting all the benefits you expect from scheduling and planning software: Shorter lead times, better on-time delivery performance, superior throughput from Production.

Resources

Customer Reviews

Your insights are valuable, be the first to rate this solution.

- Help your peers. If we all provide feedback on our business solutions, our collective wisdom will help take the pain out of purchasing decisions for everyone.

- Share feedback. Using a solution that has made your job easier or provided benefits to the team? Make your voice heard.

- Earn recognition. Your detailed, balanced reviews of the solutions that you know inside and out can position you as an expert.

Canada (English)

Canada (English)

Colombia

Colombia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malaysia

Malaysia

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri Lanka

Sri Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States