CADLink - CAD BOM to Acumatica Sync

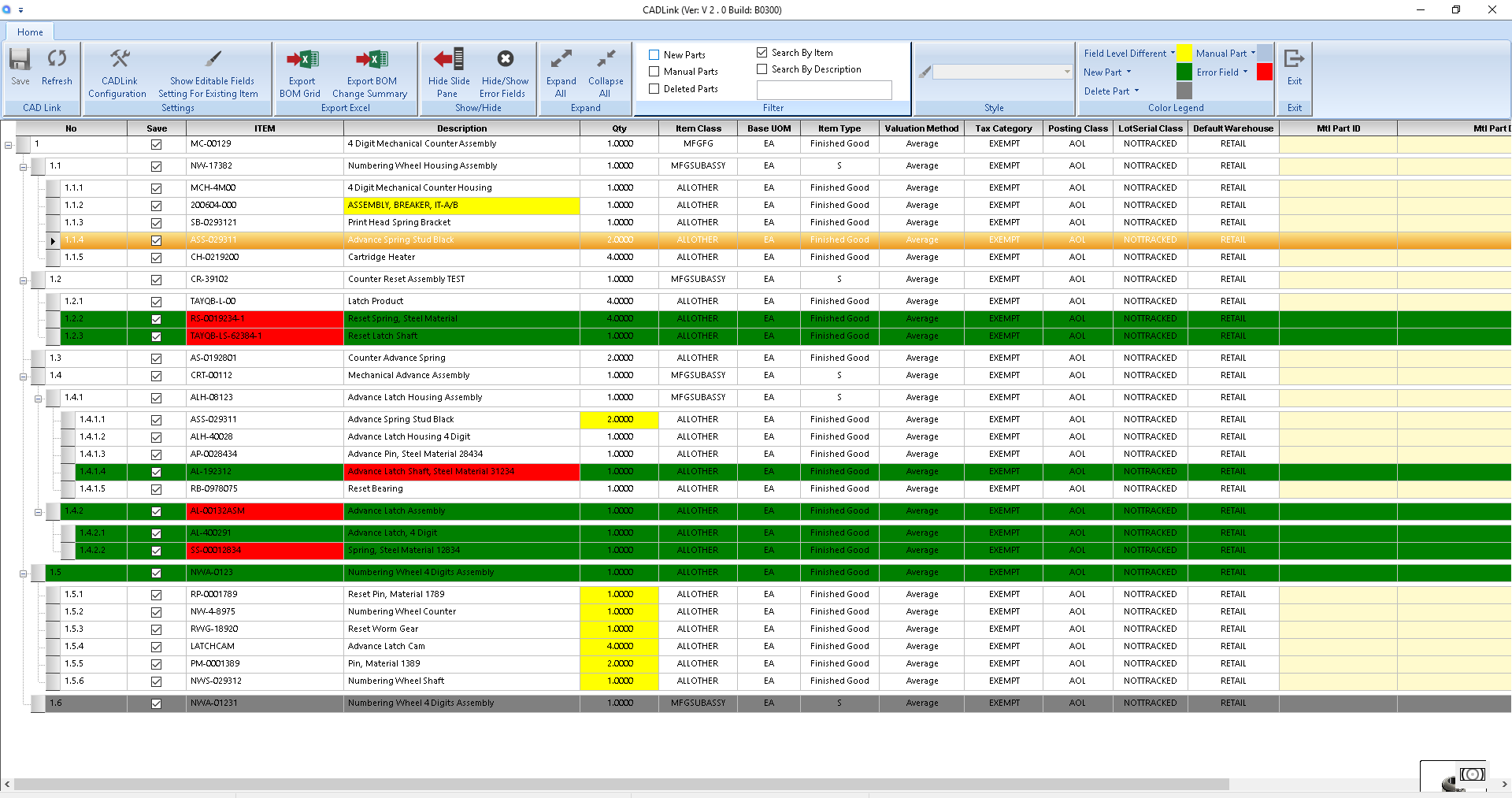

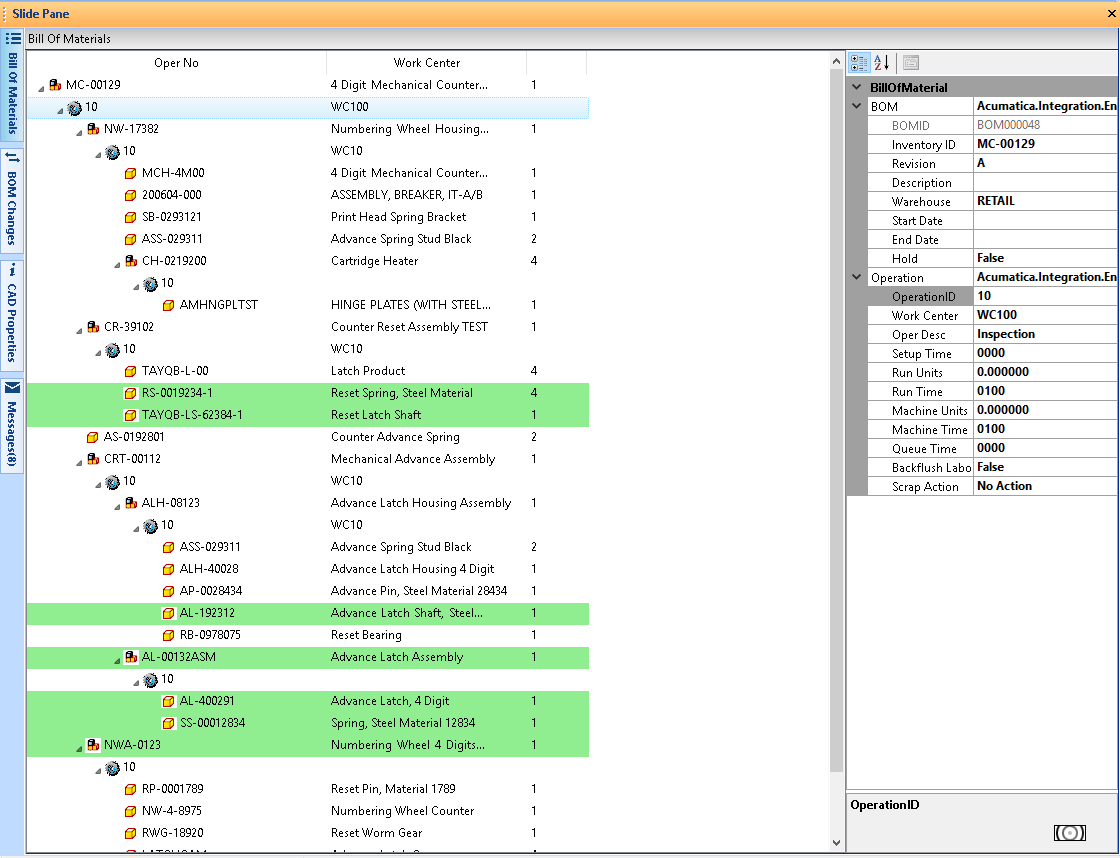

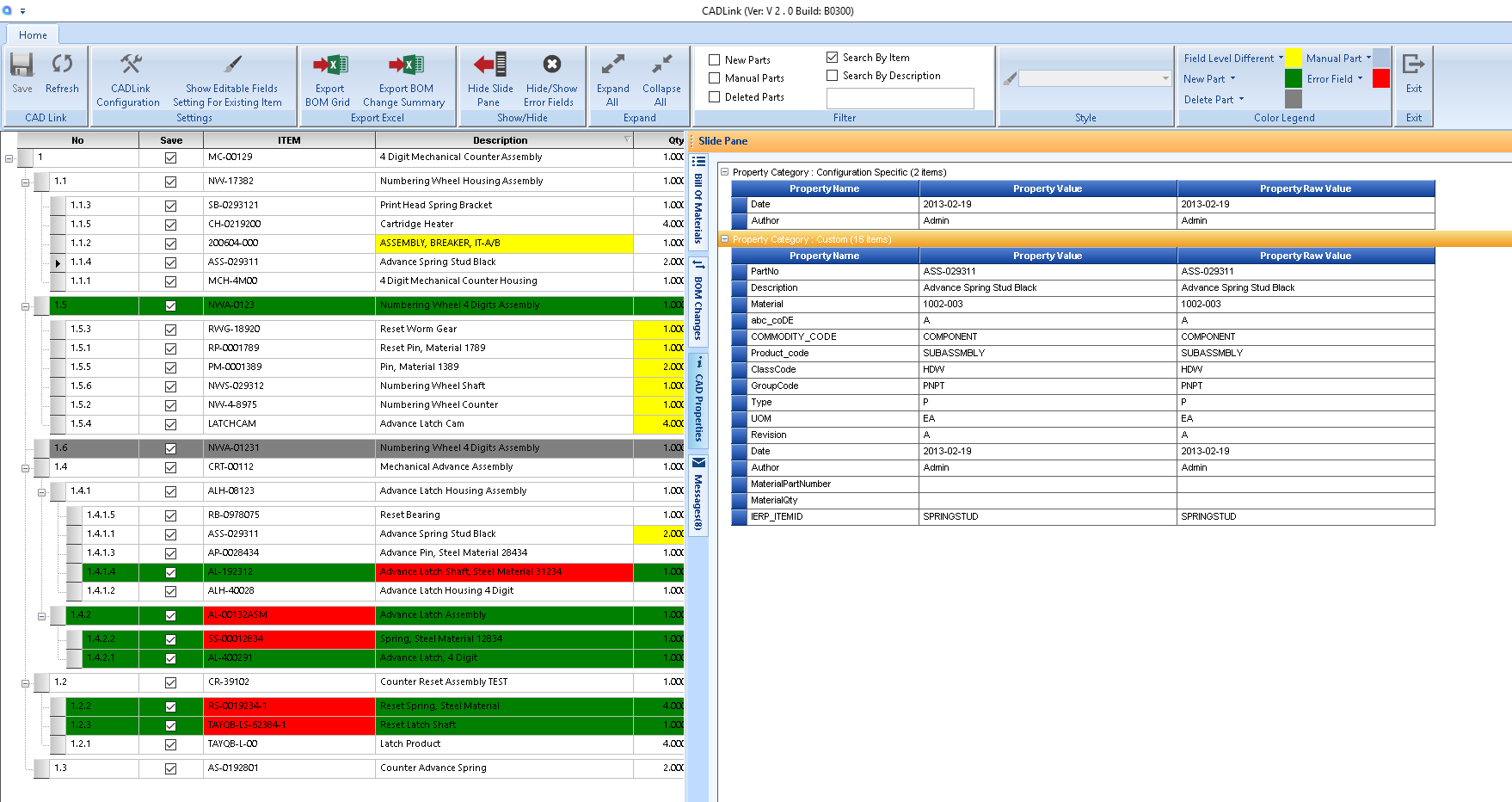

QBuild’s CADLink is designed to tightly connect CAD, PDM, and PLM systems to Acumatica. Using a real-time, bidirectional link, engineering designers can view, modify, update and create Acumatica engineering information such as Bill of Materials and Stock/Non-Stock Item record data without ever leaving your CAD system. Routings and operations can be assigned and added into Acumatica using an easy drag-and-drop interface. Engineering changes can be created by CADLink if the engineering change module in Acumatica is being used.

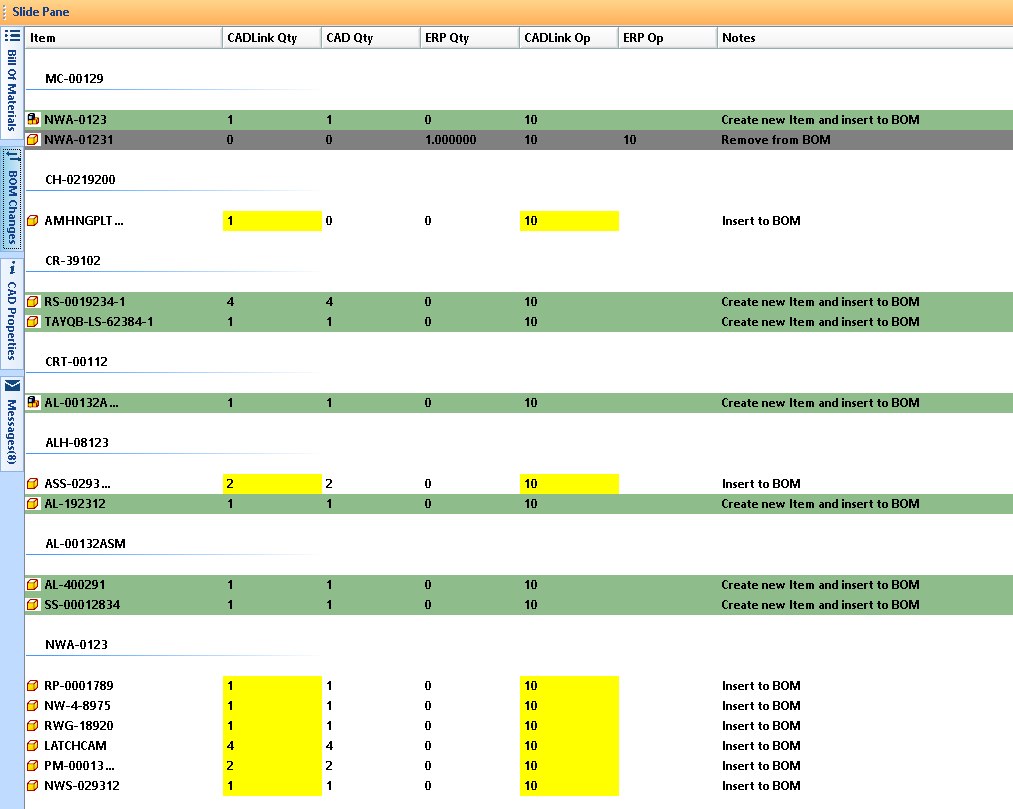

Push and pull information from your CAD system and Acumatica; Create items, draw comparisons, highlight discrepancies, and make changes to two different data sets in one interface. Reduce costly mistakes and synchronize your CAD and ERP Bill of Materials in an organized and controlled way. If you’re looking for a SOLIDWORKS Acumatica Integration, Inventor Acumatica Integration, or AutoCAD Acumatica Integration, no matter which CAD, PDM, or PLM System you use, CADLink can be the link between your design data and Acumatica.

Key features

- Direct CAD Integration: Real-time, direct, two-way link between your CAD and Acumatica means no more exporting or importing of data files. Keep your CAD and Acumatica engineering data synchronized and up-to-date at the click of a button!

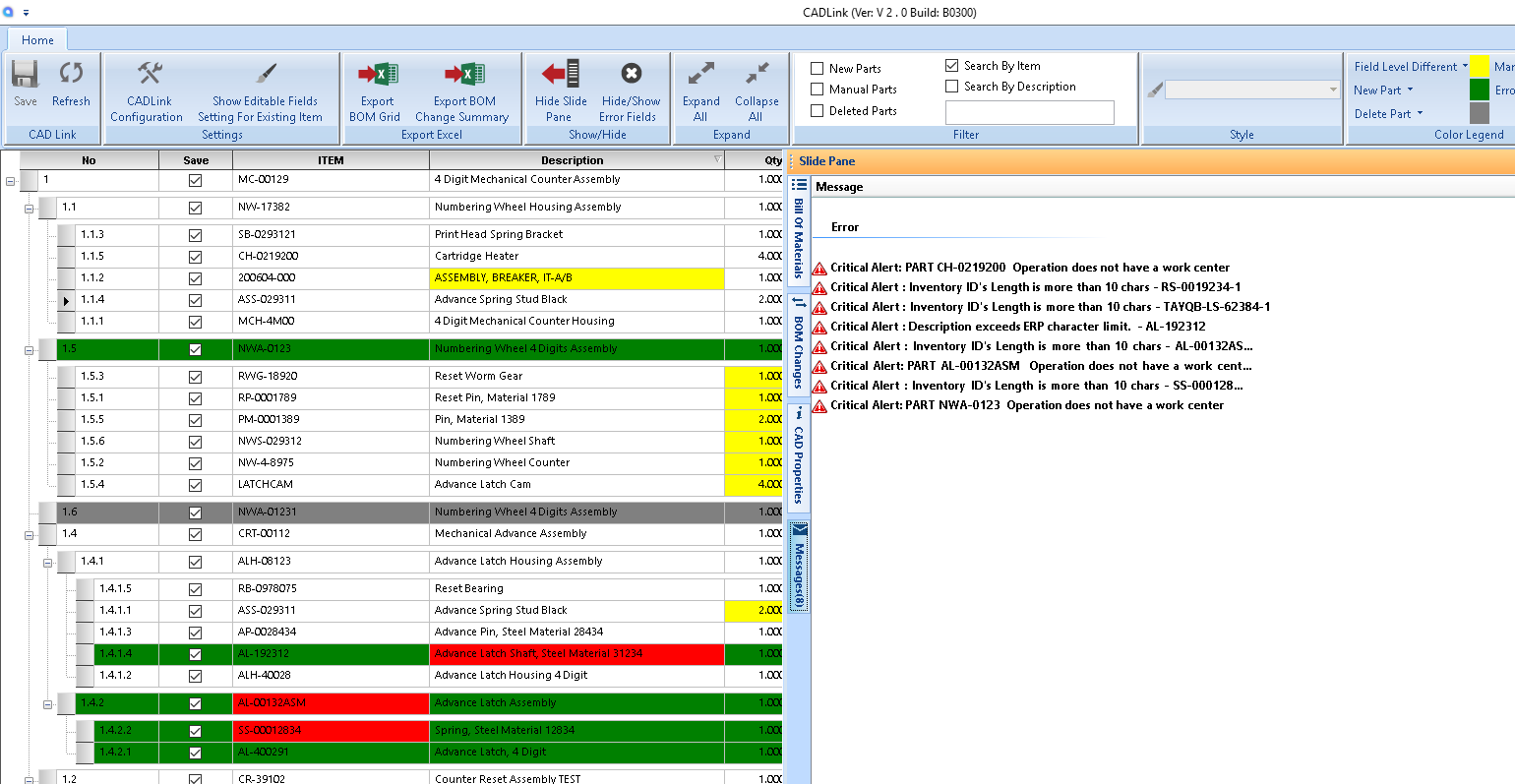

- Discrepancy and Error Notification: CADLink offers an intuitive and highly visual interface to display data discrepancies and checks for critical errors, notifying the user prior to save. Single-step process eliminating duplicate manual data entries.

- Powerful Search: Search your Acumatica records live and insert raw material items to your BOM.

- One-click Summary Reports: Easily generate PDF Bill of Material Change summary report and export Bill of Material in an Excel file format to meet your documentation requirements.

- Small Footprint: CADLink offers and easy installation and setup, and small footprint with minimum client machine hardware and software requirement.

- Quick and Easy Routing Interface: CADLink offers a simple drag-and-drop interface for creating and assigning Acumatica operations and resources on your BOM.

- Engineering Change Integration: Instead of updating the BOM directly, have CADLink create an engineering change based on the new CAD revision. This allows you to take advantage of even more Acumatica functionality with CAD as the launching point.

- Stock and Non-Stock Items: CADLink can work with both Stock and Non-Stock items in Acumatica for maximum flexibility based on the way you operate

About QBuild Corporation

QBuild Software is the industry leader in CAD-ERP integration software. For decades, QBuild has been developing integrations to increase engineering productivity, reduce costs, streamline internal ECN processes, and synchronize with nesting tools. Our flagship solution, CADLink, allows engineering designers to view, modify, update, and create engineering records in Acumatica, such as Bill of Materials (BOM) and Stock/Non-Stock Item data directly from their CAD data. CADLink is able to develop a BOM data transfer interface for any combination of CAD system with Acumatica.

Resources

Customer Reviews

CADLink's ability to compare CAD data to ERP data and then directly upload bills of materials has been invaluable. Between keeping our CAD part data up to date, and eliminating manual BOM entry it has significantly reduced engineering/purchasing errors. Best of all, the Qbuild team was able to customize CADLink to fit our needs and has always offered quick support.

After almost a year and a half floundering with various solutions, trying to bring our Inventor and Solidworks data into Acumatica - CADLink saved our company hours and hours of manual work that can be solved with just a few clicks.

From the outset, seeing the demonstration interface highlight all the information we needed enlightened us to what was possible. Through various sandboxes and setups and customizations, we are now able to bring our design department into the future and take released designs directly into Acumatica for immediate use by procurement and production.

The support from the CADLink team has also been spectacular. They're always ready for a call to field questions and explain how to operate and problem solve.

Our one wish is to have a reference guide for FAQs off the bat, learning and remembering everything about CADLink initially. That would have helped us use less of CADLink's time asking questions about something that we perhaps just forgot.

Otherwise, I myself am thrilled at getting to demonstrate the ease of use and use cases for CADLink moving forward.

We were looking for a solution to eliminate errors caused by double entry and we wanted to increase engineering throughput.

With CADLink, cost savings will drop directly to the bottom line and the engineering and operations team will significantly increase productivity.

Our problem was that Engineering was not in lockstep with Manufacturing. CADLink took care of that, and it pays for itself immediately. I really like the BOM comparison tool.

We need to export/import Bills of Material and Routing from CAD to an ERP solution. CADLink provided flexibility with many CAD solutions. The creation of part master and Bill of Material structures from the CAD solution and maintaining revision changes are great features.

We were looking to synchronize CAD and ERP Bill of Materials. The solution highlights discrepancies and make changes to two different data sets in one interface. The integration with SOLIDWORKS, Inventor, or AutoCAD is very valuable.

We wanted to make sure that our CAD system matches what is in Acumatica. I would say it is well worth the money and Qbuild is a great company to work with.

Before CADLink implementation our data was entered into our ERP manually which was a grueling process that created many headaches. We selected CADLink to automate BOM's entering our ERP to speed up manufacturing time. Having CADLink allows us to enter entire BOM's fast and efficiently rather than enter each component into our ERP manually. This software allows us to upload data in a fraction of the time & eliminates some of our major bottle necks. Instituting the software was quick & easy as the program is very user friendly & the tech support is first-class to deal with. We made the right choice in selecting CADLink.

CADLink has been fundamental in our company’s quest to implement a brand-new ERP system. Without CADLink our engineering team would be completely inundated with error-prone data entry causing unacceptable project deadlines. The team at QBuild have been very supportive during training, integration, any troubleshooting to refine the software to our needs. Thankfully with CADLink our engineering team can quickly get through the initial meta data bulk uploading and get back to our day-to-day responsibilities.

We have seen first hand the measurable results that many of our customers see with CADLink & NestLink. Not having to worry about manually entering the bill of material AND routing in Acumatica reduces potential errors that lead to higher COGS and longer lead times to your end customer. The CADLink team is very flexible and works with most of today's CAD systems. We would very much recommend CADLink as the top solution for CAD/ERP integration on the market.

Canada (English)

Canada (English)

Colombia

Colombia

Caribbean and Puerto Rico

Caribbean and Puerto Rico

Ecuador

Ecuador

India

India

Indonesia

Indonesia

Ireland

Ireland

Malaysia

Malaysia

Mexico

Mexico

Panama

Panama

Peru

Peru

Philippines

Philippines

Singapore

Singapore

South Africa

South Africa

Sri Lanka

Sri Lanka

Thailand

Thailand

United Kingdom

United Kingdom

United States

United States